Fort Lauderdale Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma history is not something that not many people think about in learning or researching when they think about being part of the industry or learning the methodology, can it is mostly because it can be difficult to keep up. There are many methodologies involved, which can make it difficult to understand. However, our team at Lean Six Sigma Curriculum for Fort Lauderdale High School Students of Florida knows best, and we can assure you that every detail about it can be shared by us and won’t make you feel confused, as we can summarize it in detail, starting right below.

We love to share the history and purpose with students before they enroll in any of our courses or training programs. We find this a common practice, and it is also because not many people take the time to research the methodology beyond the “it is an excellent way to improve processes.”

LSS is a method that places emphasis on customer satisfaction and continuous improvement. It reduces costs and eliminates waste, which is crucial to maintaining high quality and performance.

In recent years, Lean Six Sigma was reintroduced to other industries. It is no longer limited to the manufacturing industry where it was first introduced; instead, it is a tool that can be applied to many fields if the correct processes and steps are used.

Let’s take a look at the past. LSS was created to solve the problems American companies faced when Japanese companies dominated production and markets in the 1980s.

Japan used many methods to achieve this feat, including the Kaizen technique, which is widely used by companies all over the world.

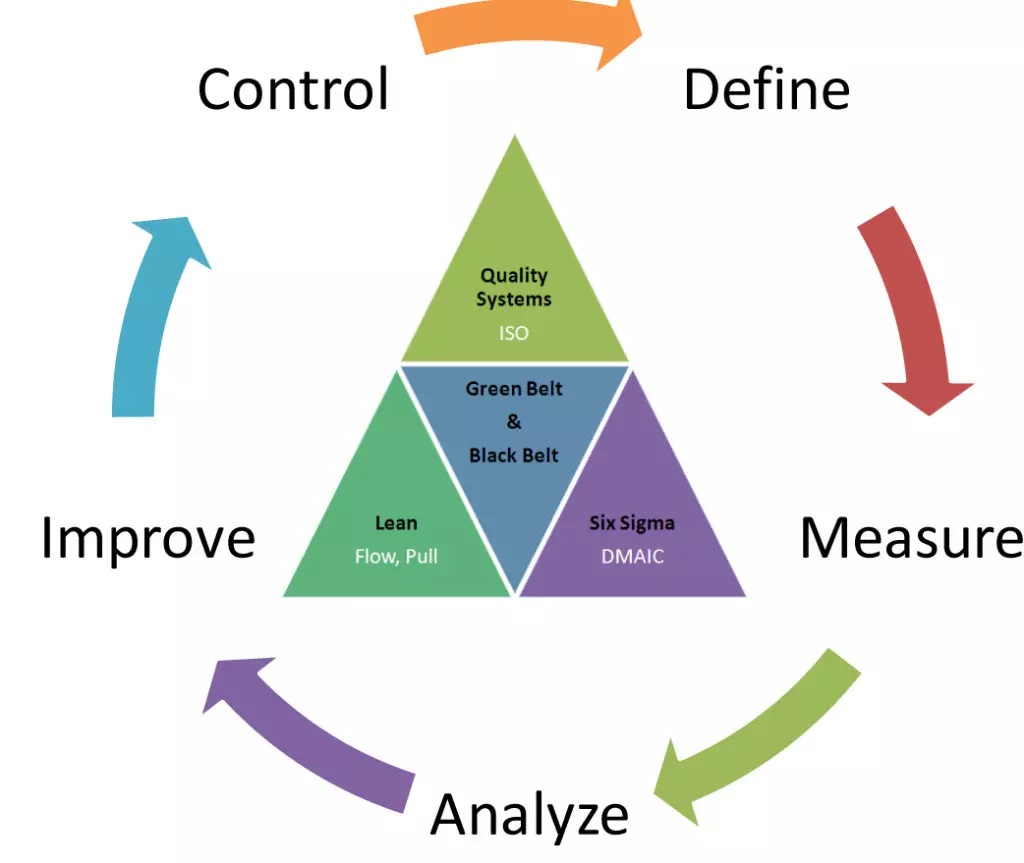

LSS’s history and the records show that Six Sigma and Lean, both American methodologies, helped improve companies’ performance and were able to compete with Japan. However, this was possible by combining both methodologies and getting LSS which also addresses several issues in terms of employee involvement.

Which Methodologies Compete with LSS?

It is essential to fully understand the history of Lean Six Sigma before you can apply it or dig deeper into its past to learn how it evolved. For it, you must learn a bit more about some methodologies:

- Kanban is a tool for workflow management.

- Kaizen is a philosophy that promotes self-improvement as well as customer satisfaction.

- Value stream mapping for optimizing process delivery.

These were all competing methods during the 80s. They are still part of LSS’s bases today because the latter wants to address all the existing ones and surpass them so that companies in the USA can reach the top.

Lean and Six Sigma are two of the most important methodologies in this history since LSS can be described as a combination of both, as mentioned earlier, and thus, it is important to go over them.

Six Sigma, Lean, and What are They?

Toyota developed Lean in the late 1940s as a way to reduce non-value-adding activities while focusing on customer satisfaction. To support Lean and ensure that companies get the best results, the Lean core values were developed.

- You can use your customers’ perspectives as a guide.

- All waste from work must be minimized.

- Keep your customers in the forefront and improve on the solutions that you provide.

Toyota Production Systems (TPS) is where Lean was first established. It is also the place where we first experience its use. According to some data, Lean was created by Henry Ford’s innovations on Business Process Redesign and other records that date back to the 1930s and 40s when they were first created.

Motorola, on the other hand, developed Six Sigma, and General Electric used it successfully at the time. Six Sigma, a process improvement technique that dates back to the 1980s, was first used to reduce variability in manufacturing processes.

It is based upon the DMAIC framework, which allows processes and wastes to be identified, measured, and analyzed. Then, they are improved and monitored to ensure continuous improvement.

The model can be used in DMADV and DFSS versions. 6 Sigma allows you to identify and measure the most important indicators within a company, so this will enable you to pinpoint areas that need improvement.

LSS for Process Improvement

Let’s consider 6 Sigma and Lean as part of our history. But let’s not forget that LSS is a mix of both and makes sure to cover other needs and gaps when people consider implementing them individually.

This method was developed in the USA and right after 6 Sigma entered the industry.

It has been used in many industries since its inception in the late 1980s. Because of its popularity, it is a valuable addition to any curriculum if you become a practitioner.

If you are interested in adding certifications and training to your curriculum, or if LSS is something you offer to students and workers, contact Lean Six Sigma Curriculum Pros of Fort Lauderdale for more information.